Yorumlar

Where It's Applied

Balanset-1A is actively applied for vibration adjustment of all sorts of rotating equipment:

Industrial Machinery:

Ventilation Units - production, centrifugal, radial. Pumping Equipment - screw, oil. Motors - DC motors. Turbines - gas. Compressors - centrifugal.

Processing Equipment:

Spindle Units - lathe. Grinding Wheels. Roll Equipment of paper machines.

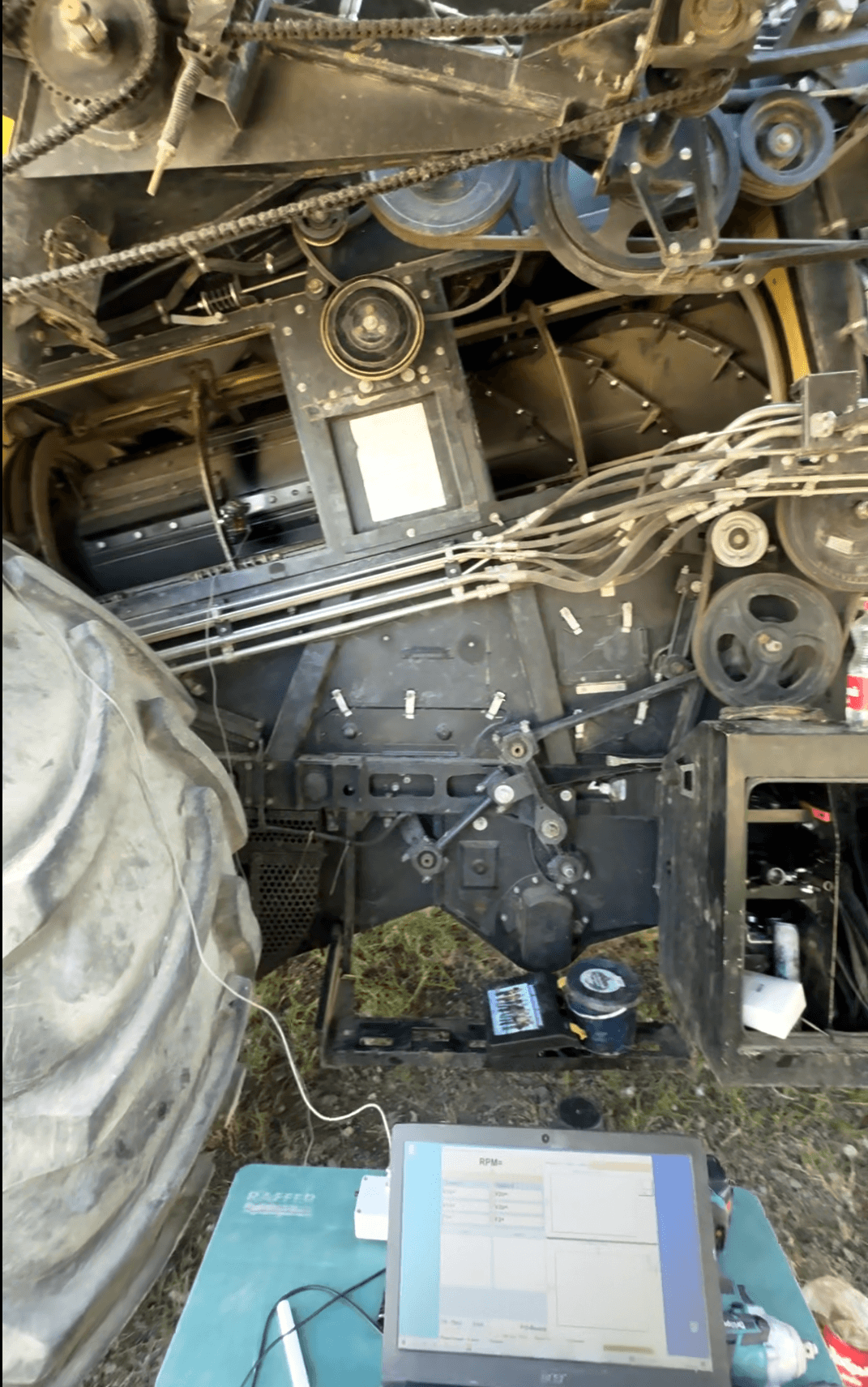

Agro Equipment:

Combine Rotors. Rotary Mowers. Crushing Units for grain.

Special Applications:

Centrifuges - medical. Air Blowers. Milling Units. Transmission Shafts.

Where It's Applied

Balanset-1A is actively applied for vibration adjustment of all sorts of rotating equipment:

Industrial Machinery:

Ventilation Units - production, centrifugal, radial. Pumping Equipment - screw, oil. Motors - DC motors. Turbines - gas. Compressors - centrifugal.

Processing Equipment:

Spindle Units - lathe. Grinding Wheels. Roll Equipment of paper machines.

Agro Equipment:

Combine Rotors. Rotary Mowers. Crushing Units for grain.

Special Applications:

Centrifuges - medical. Air Blowers. Milling Units. Transmission Shafts.

Specifications

Key Characteristics:

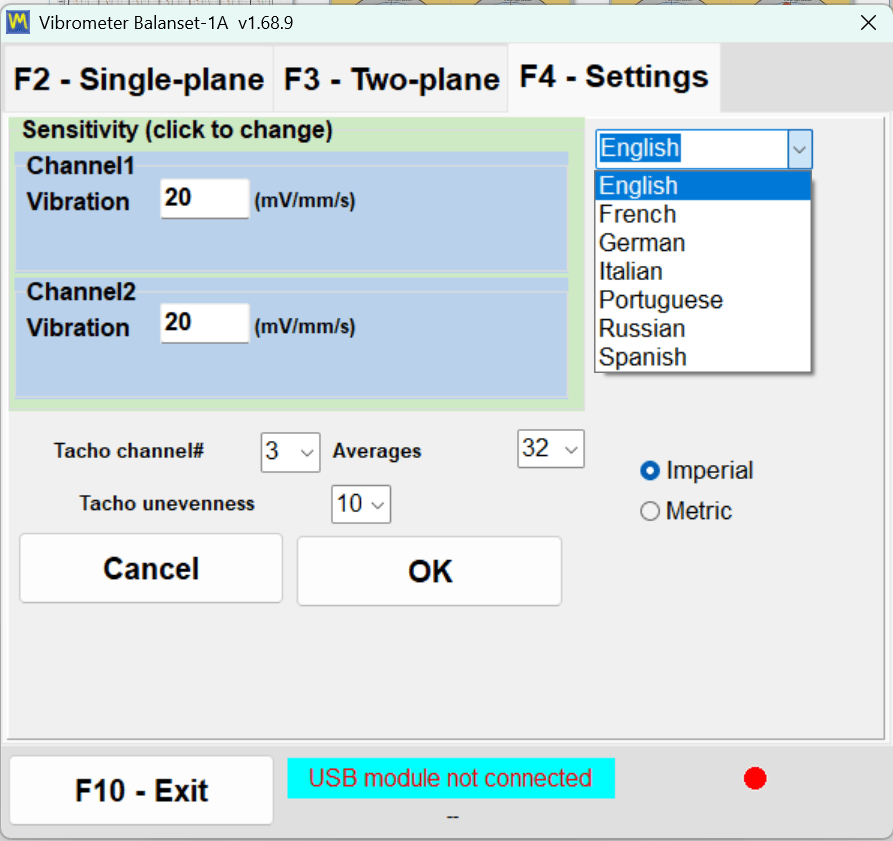

Correction planes: 1 or 2. Operating speed range: 200 to 15,000 RPM. Phase error: ±1°. Vibration error: ±5%. Number of measurement channels: 2. Vibration measurement limits: 0.1 to 300 mm/s. Power supply: USB powered. Kit weight: 4 kg.

System Capabilities:

Automatic calculation of correction masses. Database of operations. Standards determination according to ISO 1940. Frequency analysis of vibration. Graphical display in real time. Split weight calculation. Index balancing of mandrels.

Supply Composition

Standard Configuration:

USB coupling module (1 pc.) - ensures measurement control between sensors and computer.

Vibration transducers (2 pcs.) - Conversion factor: 100 mV/g. Operating frequencies: 0.5-10,000 Hz. Attachment: magnetic base.

Specifications

Key Characteristics:

Correction planes: 1 or 2. Operating speed range: 200 to 15,000 RPM. Phase error: ±1°. Vibration error: ±5%. Number of measurement channels: 2. Vibration measurement limits: 0.1 to 300 mm/s. Power supply: USB powered. Kit weight: 4 kg.

System Capabilities:

Automatic calculation of correction masses. Database of operations. Standards determination according to ISO 1940. Frequency analysis of vibration. Graphical display in real time. Split weight calculation. Index balancing of mandrels.

Supply Composition

Standard Configuration:

USB coupling module (1 pc.) - ensures measurement control between sensors and computer.

Vibration transducers (2 pcs.) - Conversion factor: 100 mV/g. Operating frequencies: 0.5-10,000 Hz. Attachment: magnetic base.

Laser phase sensor (1 pc.) - Distance: up to 1.5 m. Remote sensing for maximum safety.

Laser phase sensor (1 pc.) - Distance: up to 1.5 m. Remote sensing for maximum safety.

Holder for phase sensor (1 pc.) - Holding force: 60 kgf. Variable angles for best measurement.

Holder for phase sensor (1 pc.) - Holding force: 60 kgf. Variable angles for best measurement.

Digital scales up to 500 g (1 pc.) - Accuracy: 0.01 g. Necessary for correct weight calculation.

Software Balanset-1A - Easy-to-use design. Windows compatible. Multiple language support.

Digital scales up to 500 g (1 pc.) - Accuracy: 0.01 g. Necessary for correct weight calculation.

Software Balanset-1A - Easy-to-use design. Windows compatible. Multiple language support.

Carrying case (1 pc.) - Heavy-duty build. Protective padding for safe transport.

Technical documentation - Detailed instructions. Practical examples.

Connection cables - High-quality noise-resistant wiring.

Benefits of Balanset-1A

Technical Benefits:

? Accurate Results - Modern algorithms of signal processing provide dependable measurements.

? Portability - Small dimensions allows on-site balancing without dismantling.

? Wide Capabilities - Works with any types rotors from compact motors to large turbines.

? User Convenience - Clear controls bypasses lengthy education.

Carrying case (1 pc.) - Heavy-duty build. Protective padding for safe transport.

Technical documentation - Detailed instructions. Practical examples.

Connection cables - High-quality noise-resistant wiring.

Benefits of Balanset-1A

Technical Benefits:

? Accurate Results - Modern algorithms of signal processing provide dependable measurements.

? Portability - Small dimensions allows on-site balancing without dismantling.

? Wide Capabilities - Works with any types rotors from compact motors to large turbines.

? User Convenience - Clear controls bypasses lengthy education.

Economic Effect:

? Cost Reduction on maintenance through timely diagnostics - significant reduction of unexpected breakdowns.

? Durability Enhancement by 50-200% - properly maintained rotors lasts longer.

? Power Savings by 5-15% - smooth operation operate efficiently.

? Fast Investment Return - from 3 to 12 months depending on application frequency.

Support

Our company provides:

Operator Training - theoretical sessions in our facility. Advanced training covers complete methodology.

Expert Assistance - remote help. Phone consultations for quick problem solving.

Verification and Calibration - periodic verification to maintain accuracy.

Equipment Rental - ideal for trial operations. Monthly lease terms available.

Economic Effect:

? Cost Reduction on maintenance through timely diagnostics - significant reduction of unexpected breakdowns.

? Durability Enhancement by 50-200% - properly maintained rotors lasts longer.

? Power Savings by 5-15% - smooth operation operate efficiently.

? Fast Investment Return - from 3 to 12 months depending on application frequency.

Support

Our company provides:

Operator Training - theoretical sessions in our facility. Advanced training covers complete methodology.

Expert Assistance - remote help. Phone consultations for quick problem solving.

Verification and Calibration - periodic verification to maintain accuracy.

Equipment Rental - ideal for trial operations. Monthly lease terms available.

Commercial Terms

Valid Rates:

Balanset-1A Portable Balancer & Vibration Analyzer: €1,751.00

Balanset-1A OEM Version: €1,561.00

Additional Vibration Sensor: €90.00

Optical Sensor (Laser Tachometer): €124.00

Magnetic Stand 60 kgf: €46.00

Reflective Tape: €10.00

Commercial Terms

Valid Rates:

Balanset-1A Portable Balancer & Vibration Analyzer: €1,751.00

Balanset-1A OEM Version: €1,561.00

Additional Vibration Sensor: €90.00

Optical Sensor (Laser Tachometer): €124.00

Magnetic Stand 60 kgf: €46.00

Reflective Tape: €10.00

Shipping Conditions:

Lead time: 3-5 business days. Warranty terms: 24 months comprehensive coverage. Payment: negotiable. Transportation: international shipping via reliable carriers.

Why Choose Us

Official Supplier - genuine products with full support.

Expert Engineers with deep knowledge in vibration diagnostics.

Full Service - from delivery to service and education.

Stock Availability - quick delivery for popular models.

Custom Conditions for regular customers including special pricing.

Shipping Conditions:

Lead time: 3-5 business days. Warranty terms: 24 months comprehensive coverage. Payment: negotiable. Transportation: international shipping via reliable carriers.

Why Choose Us

Official Supplier - genuine products with full support.

Expert Engineers with deep knowledge in vibration diagnostics.

Full Service - from delivery to service and education.

Stock Availability - quick delivery for popular models.

Custom Conditions for regular customers including special pricing.

With best wishes,

Professional experts group

P.S. Ask for presentation of the equipment at your convenience and get special conditions!

With best wishes,

Professional experts group

P.S. Ask for presentation of the equipment at your convenience and get special conditions!

Vibration Diagnostics: Unlocking the Future of Machinery Performance

In the high-tech world of today, vibration diagnostics has emerged as a pivotal tool for ensuring optimal machinery performance and longevity. As industries evolve, so too does the need for sophisticated techniques that can diagnose and correct imbalances within rotating equipment. Vibration diagnostics relies on advanced instruments, such as the Balanset-1A portable balancer and vibration analyzer, which not only provide insights into the structural integrity of machinery but also enhance operational efficiency.

Understanding Imbalances: Static vs. Dynamic

To fully appreciate the scope of vibration diagnostics, it is essential to differentiate between static and dynamic balance. Static balance pertains to situations where a rotor remains stationary, and its center of gravity is not aligned with the axis of rotation. This misalignment leads to a persistent downward pull towards the heavier side. In contrast, dynamic balance addresses scenarios where the rotor is in motion, exhibiting two mass displacements that induce additional vibrations. Such dynamic imbalance occurs when unbalanced masses are situated in varying planes along the length of the rotor.

In the realm of vibration diagnostics, identifying these imbalances is crucial, as they contribute significantly to machinery wear, inefficiency, and potential catastrophic failures.

The Vibration Diagnostics Process

Vibration diagnostics involves several methodical steps aimed at rectifying imbalances within machinery. The Balanset-1A device plays a vital role throughout this process. Initially, the machine’s rotor is mounted on a balancing machine, where vibration sensors are strategically linked to ensure precise measurements. As the rotor begins to rotate, the system monitors and records initial vibration levels, creating a baseline for further analysis.

The next phase includes the installation of calibration weights on the rotor. By adding known masses and re-evaluating vibration levels, operators can observe how these additions influence the rotor's balance. This data collection is integral to understanding the adjustments required for achieving equilibrium.

Transformative Technology: Two-Plane Dynamic Balancing

The advancement of two-plane dynamic balancing has revolutionized the way industries approach vibration diagnostics. This cutting-edge technique involves measuring and correcting imbalances in two distinct planes, thus addressing complex scenarios that static balancing cannot rectify. The Balanset-1A’s two-channel capability enables simultaneous analysis, streamlining the assessment process.

During the dynamic balancing process, operators can rapidly switch weights and observe changes in vibration levels until achieving optimal results. This efficient approach reduces downtime and enhances production capabilities, underscoring the significance of vibration diagnostics in modern mechanisms.

Implementation of Vibration Sensors

Incorporating vibration sensors into the balancing process is paramount. Typically installed on the bearing housing or felt core, these sensors provide real-time data critical for diagnosing dynamic imbalances. By capturing vibrations in both horizontal and vertical directions, the sensors ensure a comprehensive understanding of the rotor's performance.

The precision of sensor placement, along with the analysis of gathered data, leads to the identification of corrective measures that can be taken. This precision is vital since even minor imbalances can result in substantial vibrations that decrease machinery efficiency over time.

The Importance of Corrective Weights

Determining the correct placement and mass of corrective weights relies heavily on detailed analytical processes. Analyzing angles and positions is essential to ensure the effective application of counterweights that will dynamically balance the rotor. The strategic calculation of trial weights based on rotor mass and speed allows operators to achieve seamless balancing.

This facet of vibration diagnostics is pivotal for industries that rely heavily on mobile and rotating machinery, where optimized performance correlates with reduced operational costs and increased productivity.

Vibration Diagnostics Across Industries

The applications of vibration diagnostics are extensive, influencing various sectors including manufacturing, agriculture, aviation, and energy. Whether it is ensuring that crushers in mineral processing plants operate without failure or keeping turbines in power generation facilities running smoothly, the deployment of effective vibration analysis tools is a game changer.

Beyond fault detection, vibration diagnostics contributes to the predictive maintenance culture emerging in industry today. This proactive approach allows companies to mitigate risks associated with machinery failure through early identification of potential issues, enhancing operational efficiency.

The Future of Vibration Diagnostics

As industries gear towards greater automation and intelligence, the future of vibration diagnostics looks promising. Rapid advancements in technology, including artificial intelligence, machine learning, and data analytics, are paving the way for even more sophisticated tools that offer deeper insights into machinery behavior. These innovations promise not only to enhance traditional vibration diagnostics but also to introduce predictive models that anticipate failures before they occur.

In essence, vibration diagnostics stands at the forefront of a revolution in machinery maintenance and performance optimization. By leveraging advanced equipment like the Balanset-1A and embracing a culture of precision engineering, industries can achieve higher standards of machinery reliability, efficiency, and longevity.

Conclusion

The integration of vibration diagnostics into industry practices not only streamlines maintenance processes but also fosters a culture of efficiency and proactive management. As technological innovations continue to unfold, the future beckons with the prospect of revamped approaches to machinery diagnostics, ensuring that industries remain competitive and effective in the face of rigorous demands.

Белый Диплом Это

Уезжали на длительные срока или просто пропадали, раздавленные консолидированной машиной коррумпированных сил МэВэДэ. В отличие от степени магистра, бакалавриат является первой ступенью высшего образования. Не откладывайте решение данного диплома в дальний диплом, займитесь получением диплома об образовании уже в ближайшее время.Доверенность На Пользование Автомобилем

Бакалавр, диплом, магистр, дипломы колледжа и школьные аттестаты. Мы следим за правильностью предоставленной информации, чтобы вы получили "корочку" с помощью которой сможете найти работу. Наша задача помочь Вам стать ещё более индивидуальным и неповторимым.Купить Диплом О Среднем Образовании В Пензе

Ломоносова (мгу), московский государственный университет международных отношений (мгимо), московский авиационный институт (маи), московский государственный технический университет имени н. На самом деле сделать это не так сложно возможно, такие компании знает кто-то из ваших родственников или друзей. С таким документом можно получить желаемую должность и двигаться по карьерной лестнице только вперед.Купить Диплом О Высшем Образовании В Ульяновске

Поэтому, заполняя форму заказа, не беспокойтесь о том, что кто-то узнает о нашем сотрудничестве. А может, у вас просто нет денег для свидетельства О Рождении 2016 высшего образования. Мы указываем требуемые баллы по дисциплинам, выставляя их во вкладыше к диплому. Некоторые университетские специальности по теоретическому и практическому наполнению почти идентичны, но одна формулировка в дипломе пользуется спросом, а другая считается устаревшей или непонятна работодателю.Yorum Yap

Zenne Spor 527

ÜRÜN ÖZELLİĞİ

TABAN FALYON MALZEME STREÇ SUMİ ANORAK

RENK

BEYAZ | BUZ | LACİVERT | SİYAH BEYAZ | SİYAH PLATİN | SİYAH | HAKİ | FÜME KAMUFLAJ | PETROL

KOLİ ASORTİSİ

36-1

| 37-2 | 38-2 | 39-2 | 40-1